All About Premier Aluminum Llc

All About Premier Aluminum Llc

Blog Article

Excitement About Premier Aluminum Llc

Table of ContentsThings about Premier Aluminum LlcThe Only Guide to Premier Aluminum LlcThe Ultimate Guide To Premier Aluminum LlcThe Ultimate Guide To Premier Aluminum LlcGetting My Premier Aluminum Llc To Work

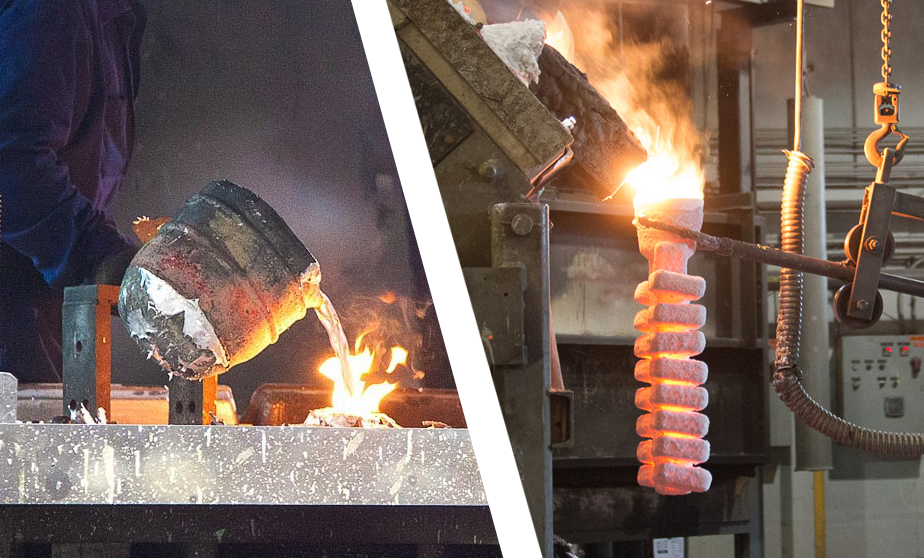

When choosing an aluminum foundry for your production needs, it's crucial to examine several factors. Among one of the most crucial facets to think about is the experience and proficiency of the foundry. Selecting a factory that has the best knowledge of the aluminum casting process, and the portfolio to show for it, aids to have a successful outcome for your job.Having the experience and sector understanding to craft your castings for optimum manufacturing and top quality outcomes will certainly improve the job. Producing light weight aluminum spreading calls for a complicated set of procedures to achieve the ideal results. When picking a brand-new aluminum shop to partner with, ensure they have comprehensive sector experience and are knowledgeable regarding all aspects of the aluminum casting process: layout, production, material evaluation, and item testing.

The shop should likewise have a proven performance history of providing extraordinary products that satisfy or surpass consumer assumptions. Quality assurance must additionally be at the top of your listing when picking a light weight aluminum foundry. By dealing with a certified foundry that follows the criteria for quality assurance, you can shield the honesty of your item and guarantee it satisfies your specifications.

Premier Aluminum Llc - An Overview

This certain process can be automated and duplicated. Different elements that very made complex forms can be produced using this procedure. Consequently, big volumes of parts can be created in just a short time period. Before you start looking for a dependable aluminum die caster, there are some crucial things that you need to do first.

You need to ask on your own what kind of aluminum die castings you need. After identifying what you need, you need to mention the specs of the aluminum pass away castings you need. Determine the weight, density, size, and various other specifications of the aluminum die-cast you call for. It would also be a lot better if you might attract and reveal all the measurements of the aluminum die-cast.

After having this details, you can start investigating light weight aluminum die-casting producers. You can do this by just inputting the key phrase" Light weight aluminum pass away casting producers" on the Google search engine.

Some of the inquiries you need to ask on your own are whether they have experienced and trained operators, the length of time their organization has actually functioned, or if they have some success. You can often obtain the solution to these questions from the producer's site. You can investigate other websites or external sources to confirm if the information provided on the supplier's internet site discover this is genuine.

Premier Aluminum Llc Fundamentals Explained

Another thing you have to consider is the maker's capacity to create aluminum die-casting products. Simply put, the quantity of products the supplier can produce at a given time. Several of the essential questions you need to ask on your own are whether the producer can generate a greater quantity or can the supplier satisfy your needs.

(https://my-store-1033190-2.creator-spring.com/)Suppose your business requires 10,000 items of particular machine components from the producer within one month? You got this quantity; however, the supplier can just generate 5000 items of these equipment parts within one month (Aluminum Foundry). Consequently, you won't have the ability to get the amount that you order in a timely manner

Rumored Buzz on Premier Aluminum Llc

It is essential that you ought to inquire if the maker is executing an in-house tooling process. Additionally, you have to ask the maker just how much the expense of internal tooling is. The internal tooling process, which permits you to produce unique designs and shapes can be an extra expense.

This aspect directly correlates with the supplier's production ability. You need to look for a maker that can guarantee quicker shipment of items. This must be done in such a method that premium criteria are maintained. This can ensure that you can obtain your products on time, and you can prevent missing those important business chances.

This implies that there are a number of choices that you can pick from. Today, consumer needs continue changing. It seems that clients are looking for an outstanding mix of top quality, cost-effectiveness, and resilience. That is why it is significantly advised that you need to pick a producer that can produce various sorts of light weight aluminum die-cast products.

The 2-Minute Rule for Premier Aluminum Llc

Usually, these aluminum die-casting items will certainly require some designs, machining, or finishing touches. Having this in mind, you should try to find a maker that can execute a range of additional completing works when pass away spreading is done. Some examples of completing procedures include Chromating, CNC Machining, Sandblasting, Powder covering, Anodized, E-coating, Wet paint, Plating, and much more.

Pass away casting is one of the most cost-efficient, exact, and protean manufacturing processes in the world minute. The procedure involves fitting molten significance, under stress, right into a suitable die (planet), and previously solidified it can be ejected and ended up (if needed) in a variety of methods. Report this page